Let’s talk trash!

Singapore has a Zero Waste Masterplan, and one of its aims is to increase the country’s rate of recycling to 70% by 2030. So far, it looks like we’re doing quite well.

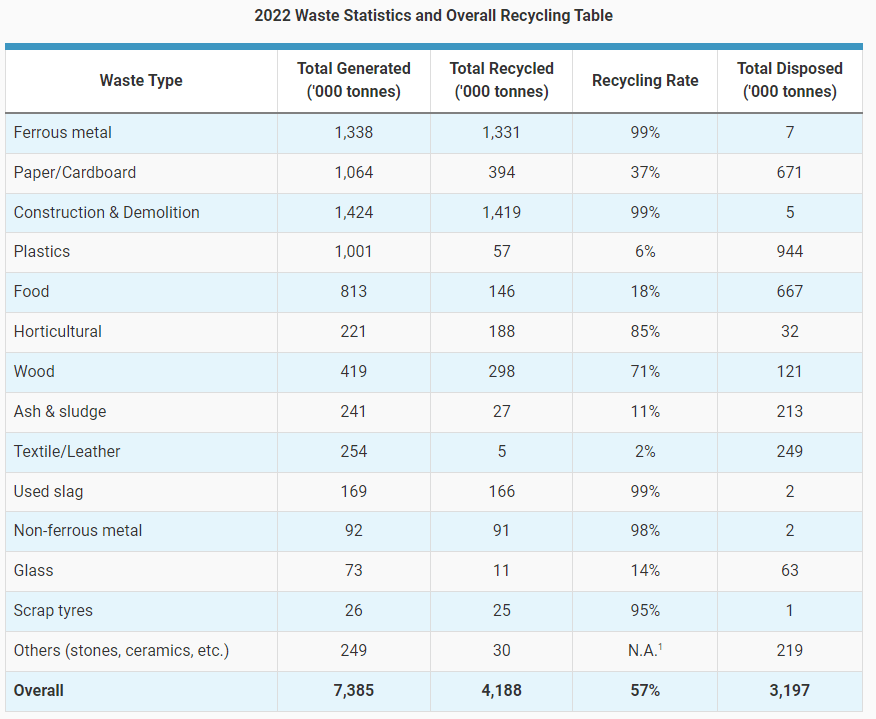

According to the National Environment Agency, the Construction & Demolition industry incurred the greatest volume of waste in 2022 – a whopping 1,424,000 tonnes!!!

Thankfully, because of great strides made in recycling, we’ve managed to recycle 99% of that, resulting in only 5,000 tonnes disposed. Just from the Construction & Demolition industry alone, we are doing very well, surpassing the goals we’ve set to achieve.

But, is that enough?

Because in that same year, we’ve also incurred 6% more waste in 2022, thanks to the Construction & Demolition industry, as well as ferrous metals disposal.

We aren’t actually getting better at reducing waste.

We’re just getting better at handling waste.

Let’s let that irony sink in for a minute.

Here’s another ironic fact:

According to an article published by Channel News Asia, recycling of wood products went down because of the increase in the amount of wood waste from the construction industry (and other industries), and there weren’t enough workers to sort through them all.

That’s a lot of wood waste going into the landfill.

Why Does This Matter?

Simply put – because we have no space for all that trash.

As it is, we are struggling with space thanks to limited land and high population density. As we continue to strive for economic growth, our rate of waste production will only increase.

If we continue on this vein, we will need to find more land to convert into expensive incinerators and landfills.

How expensive?

In 1995, $610 million (approx. $973 million today) was invested to build a new landfill between Pulau Semakau and Pulau Sakeng. In April 1999, it was opened because the landfill at Lorong Halus was exhausted.

The Semakau Landfill is now our only landfill in operation. It is projected to be exhausted by 2035.

And, at the rate we’re going, we’ll need to build new incinerators every 7 to 10 years.

So, how can we do better?

The 3 R’s

Reduce, Reuse and Recycle – we are all familiar with the 3 R’s.

But, did you know that we are supposed to follow this refrain in that order?

With that in mind, how can we in the Construction industry Reduce and Reuse first, before Recycling?

Solution: Reusable Building Materials

Instead of discarding building materials to be sorted, recycled, and disposed of, we could skip the need to recycle by reusing building materials, where possible.

Example #1: Tobermore’s Interlocking Paving Blocks

Paving blocks are often wasted post-installation.

This happens when underground works have to be done, and paving blocks which have been cemented down are ripped out. Alas, the process of doing so damages them and they have to be discarded and replaced with new pieces.

However, with Tobermore’s interlocking paving blocks, they can removed simply by lifting them up. This is because they are not mortared down to the sub-base.

Not only does this make it very easy to do any electrical or plumbing work under the pavement, it is just as easy to put those pieces back too. There’s no need to discard old paving blocks, and no need to purchase new paving blocks.

Example #2: Tobermore’s Gravity Retaining Wall

Here’s another solution that can be installed without need for mortaring.

Tobermore’s Gravity Retaining Wall has been designed to be easily installed, uninstalled, and reinstalled again. Just like building blocks!

The result?

A strong, sturdy, and aesthetic wall that can be easily dismantled and rebuilt every time underground works have to be conducted. No waste. No replacement costs.

It’s that easy.

We can reduce our need for more paving blocks by reusing them.

And by not needing to recycle them, energy, effort and manpower can be expended elsewhere.

Unconvinced?

Look out for part 2 of this article where we cover the life-cycle costs of our construction choices!